Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit needs.

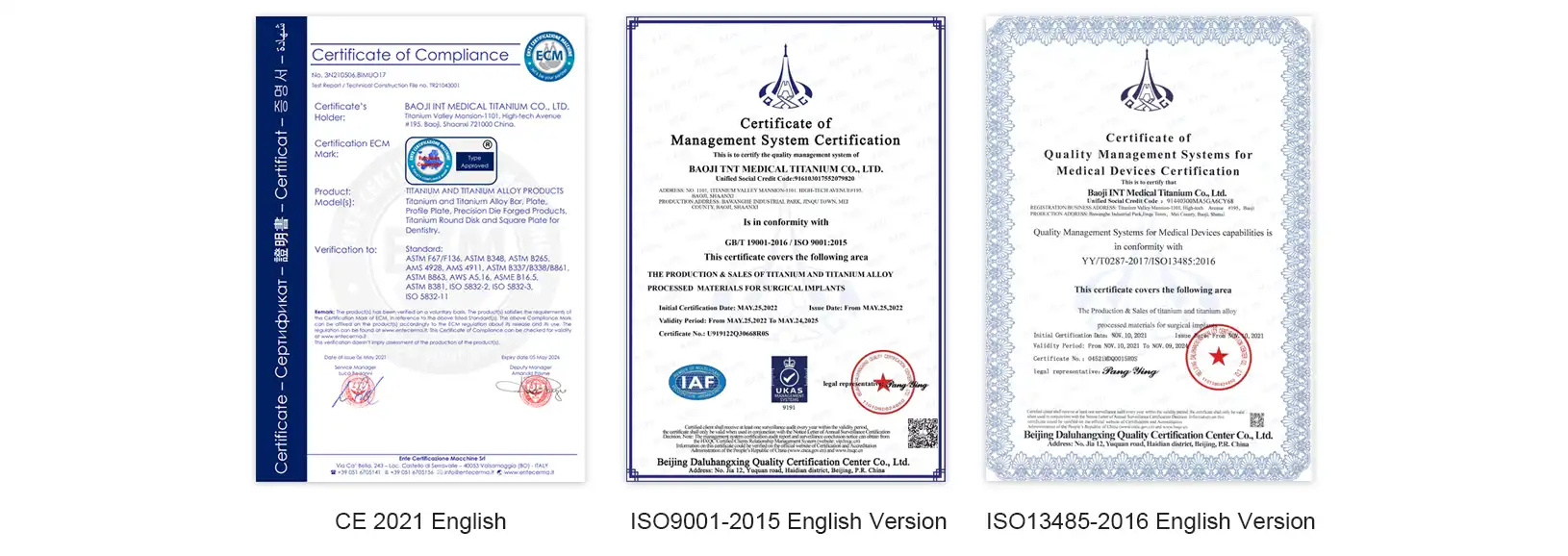

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

Gr 7 Titanium Plate Introducton

The Gr 7 Titanium Plate from Baoji INT Medical Titanium Co., Ltd. is a top-tier medical titanium material known for its corrosion resistance and biocompatibility. Designed specifically for medical applications, this product is ideal for use in various medical devices, implants, and surgical instruments.

Product Specifications

| Parameter | Details |

|---|---|

| Material | Gr 7 Titanium (Titanium-Palladium Alloy) |

| Thickness | 0.5mm - 50mm |

| Width | Up to 1000mm |

| Length | Up to 3000mm |

| Corrosion Resistance | Excellent |

| Certification | ISO9001:2015, ISO13485:2016, EU CE |

| Customization | Available upon request |

Product Advantages

- Corrosion Resistance: With the addition of palladium, Gr 7 Titanium Plate offers superior resistance to corrosive environments, making it highly suitable for medical implants and instruments.

- Lightweight and Durable: The high strength-to-weight ratio makes this titanium plate ideal for medical devices requiring strength without added bulk.

- Biocompatibility: It integrates well with human tissue, making it safe for long-term implantation.

- Certified Quality: All products meet international safety certifications, ensuring compliance with global standards.

Technical Features

- High Strength: The product maintains excellent mechanical properties, ensuring stability and longevity in medical devices.

- Excellent Fatigue Resistance: Designed to withstand repeated use, this titanium plate is ideal for demanding medical applications.

- Customization Available: Our products can be customized to meet the specific size and application needs of your project.

Gr 7 Titanium Plate Application

The Gr 7 Titanium Plate is broadly used in different clinical fields because of its remarkable properties, which pursue it an optimal decision for various basic applications:

- Muscular Inserts: The Grade 7 titanium plate is especially appropriate for muscular embeds like bone screws and joint substitutions. Its superb biocompatibility guarantees a positive collaboration with human tissues, which is fundamental for implantable gadgets. These implants are stable and reliable as a result of the material's strength and resistance to corrosion, facilitating efficient healing and integration with bone structures.

- Careful Instruments: Additionally, this titanium plate is utilized in the production of scalpels, forceps, and other precision surgical instruments. Its strong strength, joined with unrivaled consumption opposition, guarantees that these instruments keep up with their exhibition and sharpness after some time. Grade 7 titanium's lightweight but long-lasting properties make it easier to handle and make surgical procedures more effective.

- Dental Inserts: The Grade 7 titanium plate is used for dental prosthetics because it is both durable and safe. Its biocompatibility and protection from erosion make it a magnificent material for making dependable and durable dental inserts. The material's properties guarantee that dental reclamations perform actually and coordinate well with the encompassing oral tissues.

- Injury Obsession Gadgets: In trauma fixation, where it is used in plates, screws, and other long-term implants for fracture repair, the Grade 7 titanium plate is essential. Its solidarity and flexibility make it ideal for enduring the mechanical burdens related with bone mending and adjustment. This guarantees dependable and solid help during the recuperation cycle, supporting powerful crack administration.

- Spinal Inserts: For spinal medical procedures, the Grade 7 titanium plate upholds spinal combination and adjustment methodology. Its high strength and biocompatibility offer fundamental help for spinal inserts, guaranteeing steadiness and advancing fruitful combination of spinal sections. The material's strength adds to long haul spinal wellbeing and usefulness, making it a basic part in spinal embed applications.

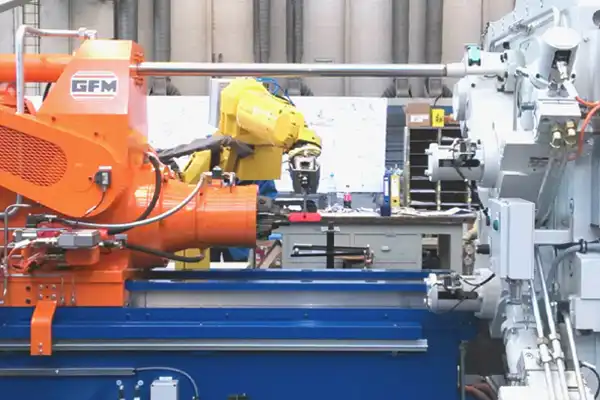

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.

Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

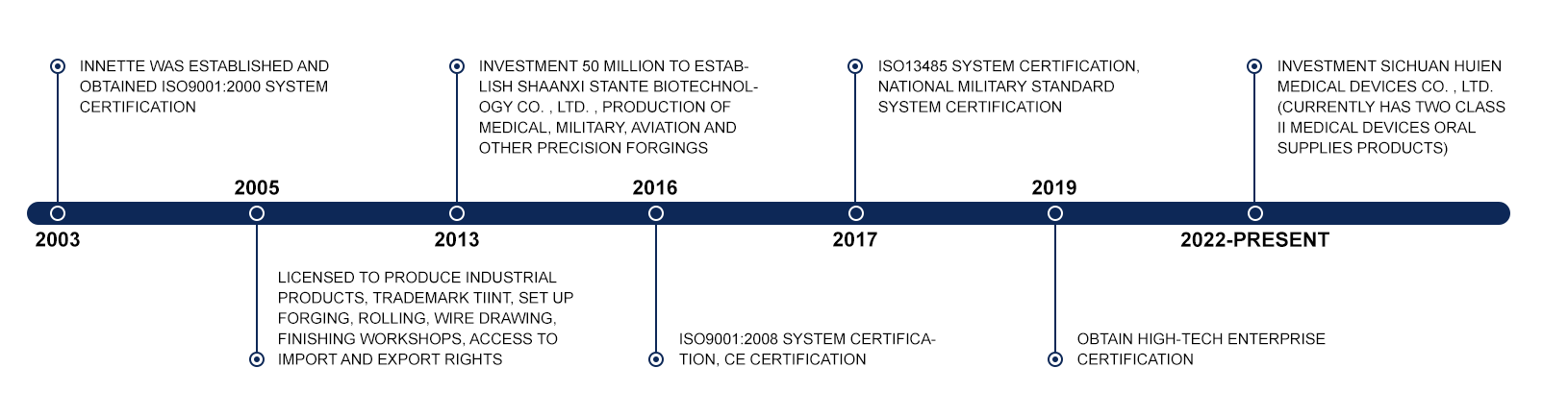

Our Factory - A Legacy of Excellence

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Service

We offer OEM services to meet your specific production needs and specifications. Our group offers master specialized help, guaranteeing your Gr 7 Titanium Plate items are custom fitted for explicit applications, whether for inserts or careful apparatuses. We are focused on opportune creation, great guidelines, and cutthroat valuing to meet your inventory needs.

FAQ

-

Q: What is the advantage of Gr 7 Titanium over other grades?

A: Gr 7 Titanium offers enhanced corrosion resistance due to the presence of palladium, making it particularly suited for medical applications exposed to body fluids. -

Q: Can I request custom sizes?

A: Yes, we offer customization options to meet specific dimensions and specifications for your projects. -

Q: What certifications do you hold?

A: Our products are certified under ISO9001:2015, ISO13485:2016, and carry the EU CE mark for medical devices. -

Q: How long does it take for an order to be processed?

A: Processing time varies based on order size and customization. We aim to deliver all orders promptly to meet your production timelines.

Contact Us

Ready to place an order or need more information about our Gr 7 Titanium Plate? Reach out to us at export@tiint.com, and we’ll be happy to assist you with your medical titanium needs.