Lightweight and extremely durable material.

Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit surgical needs.

Reliable in critical medical environments.

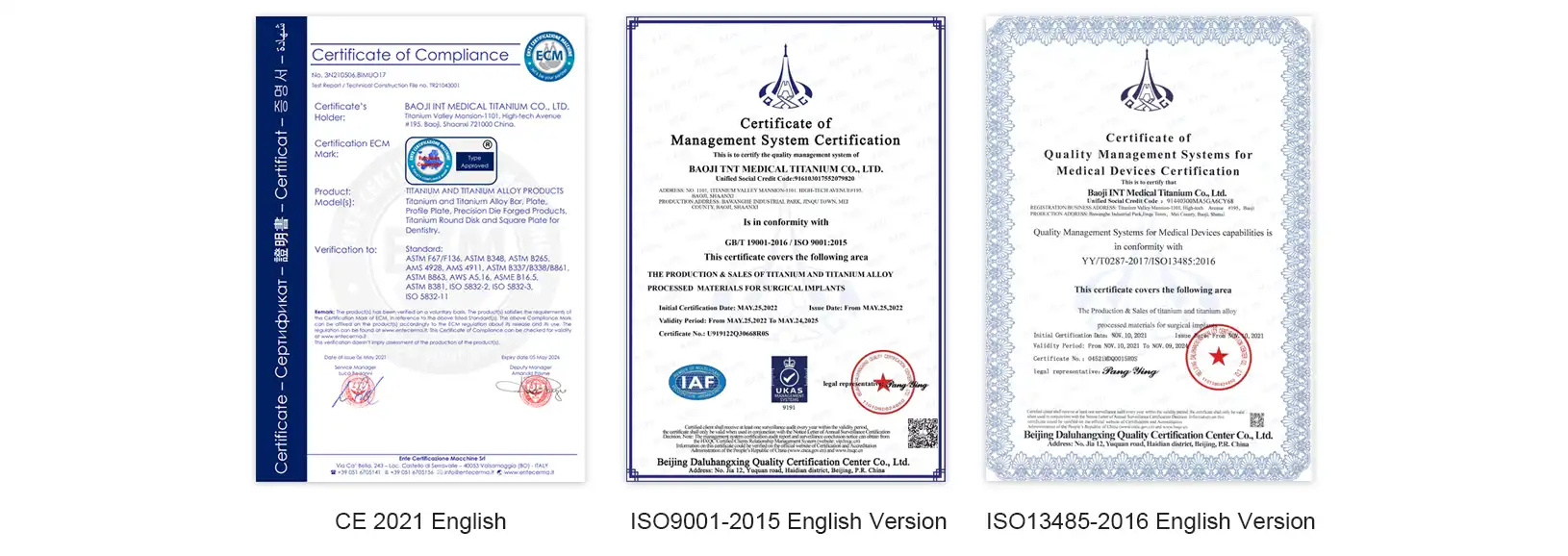

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

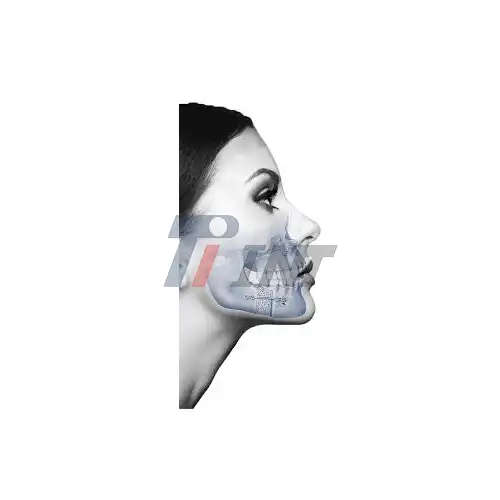

Jaw Surgery Titanium Plates

At Baoji INT Medical Titanium Co., Ltd., we specialize in providing high-quality, biocompatible jaw surgery titanium plates designed to meet the rigorous demands of modern medical applications. With decades of experience in the medical titanium industry, we offer a range of customizable solutions to enhance the safety, reliability, and performance of jaw surgeries worldwide.

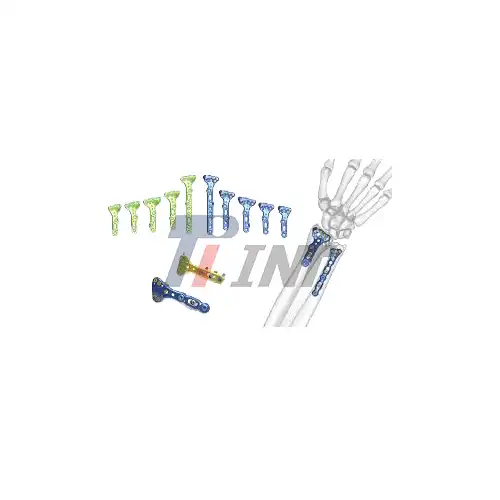

Product Specifications

| Material | Pure Titanium, Ti6Al4V, Ti6Al4V ELI |

|---|---|

| Corrosion Resistance | Excellent |

| Strength-to-Weight Ratio | High |

| Biocompatibility | Excellent |

| Fatigue Resistance | High |

| Certification | ISO9001:2015, ISO13485:2016, EU CE Certified |

| Custom Options | Available for various surgical needs |

|

|

Product Advantages

- Biocompatibility: Our titanium plates ensure excellent compatibility with human tissue, reducing the risk of rejection and enhancing patient safety.

- Corrosion Resistance: Resistant to the corrosive effects of body fluids, guaranteeing long-lasting performance.

- Lightweight: Titanium’s high strength-to-weight ratio offers flexibility without adding unnecessary bulk to the jaw region.

- Durability: Exceptional fatigue resistance ensures the plates can withstand the stress and strain of everyday use.

- Customizable: We offer a variety of shapes and sizes to meet specific surgical requirements.

Technical Features

Our jaw surgery titanium plates designed for jaw surgery come with a suite of exceptional features that address the demanding needs of modern surgical procedures:

High Strength: These plates are engineered to deliver unparalleled support, crucial for effective bone fusion and stabilization in jaw surgeries. The robust construction ensures that the plates withstand the mechanical stresses involved, providing a stable environment conducive to optimal healing and long-term stability.

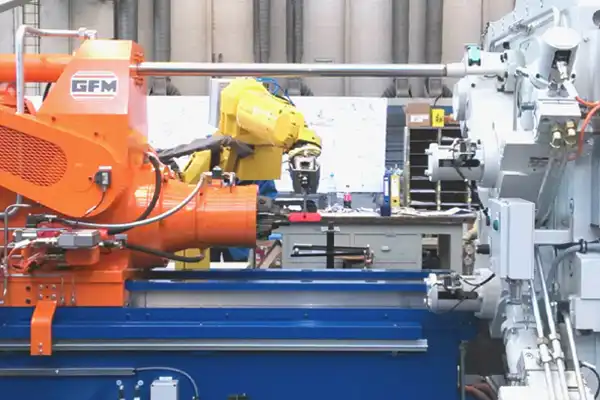

Precision Manufacturing: Utilizing cutting-edge CNC (Computer Numerical Control) technology, our plates are manufactured to exacting standards. This advanced process guarantees a precise fit, which is essential for achieving surgical accuracy. The meticulous craftsmanship ensures that each plate aligns perfectly with the anatomical structures, enhancing surgical outcomes and minimizing potential complications.

ISO Certified: Our products adhere to the highest international standards, being certified under ISO9001:2015 and ISO13485:2016, as well as receiving EU CE safety certification. These accreditations underscore our commitment to quality and safety, assuring compliance with rigorous global medical standards. This level of certification reflects our dedication to maintaining excellence in both product design and manufacturing practices.

Product Application

Our jaw surgery titanium plates for jaw surgery are meticulously designed to meet the diverse needs of complex oral and maxillofacial procedures:

Orthognathic Surgery: These plates are crucial for correcting jaw deformities, delivering steadfast support throughout the surgical process and ensuring optimal stability during the recovery phase. Their robust design helps achieve precise alignment and enhances the overall effectiveness of corrective jaw surgery.

Maxillofacial Trauma Repair: In cases of trauma, our plates play a pivotal role in the repair of fractures and bone defects within the jaw region. Their high-strength material and precise fit facilitate effective stabilization, promoting accelerated healing and improved outcomes for patients recovering from traumatic injuries.

Dental Reconstruction: For dental implants and reconstructive jaw surgeries, these plates provide the essential structural support required. They ensure the stability of dental implants and contribute to the successful integration of reconstructive procedures, thereby enhancing both functionality and aesthetics in restorative dental work.

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

Our Factory - A Legacy of Excellence

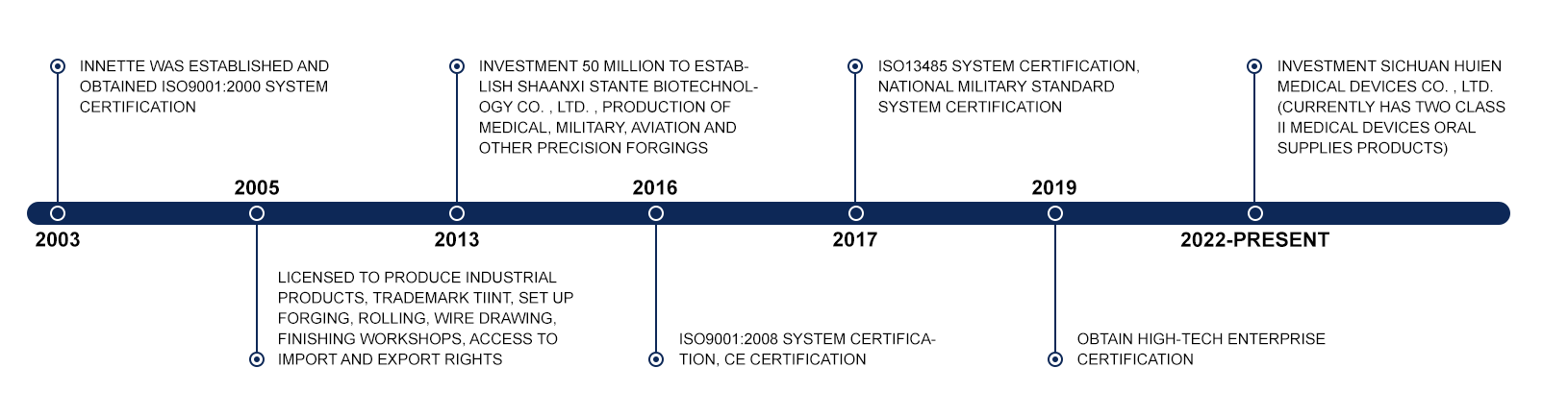

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Service

We offer tailored OEM services to meet the unique needs of our clients. Whether you require specific dimensions, surface finishes, or technical modifications, we can customize our titanium plates to your exact specifications. Our team is ready to collaborate closely with you, ensuring your product meets both your quality and performance requirements.

FAQ

Q: What material is used for the jaw surgery titanium plates?

A: Our plates are made from biocompatible pure titanium and Ti6Al4V ELI alloys, designed for medical use.

Q: Are your products certified?

A: Yes, all our titanium plates are ISO9001:2015, ISO13485:2016, and EU CE certified.

Q: Do you offer custom sizes?

A: Absolutely. We can provide customized dimensions and designs according to your surgical needs.

Q: How do you ensure product quality?

A: Every product undergoes strict quality control, ensuring compliance with international standards and flawless performance in medical environments.

Contact Us

To learn more about our jaw surgery titanium plates or to place an order, contact us at export@tiint.com. We’re here to provide the best solutions for your surgical needs.