Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit needs.

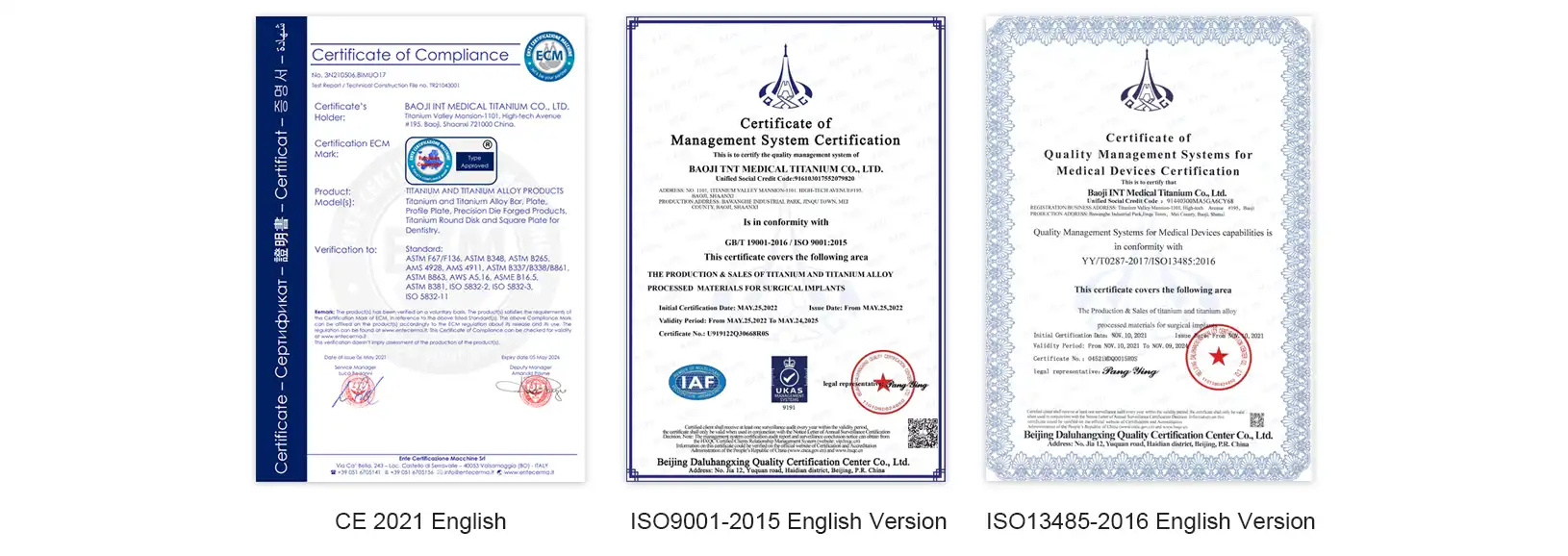

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

Gr9 Titanium Foil Introduction

Gr9 Titanium Foil is a high-performance titanium alloy product designed for medical and industrial applications. Known for its superior strength, corrosion resistance, and lightweight properties, Gr9 titanium (also referred to as Ti-3Al-2.5V) stands out as an essential material in various fields, particularly in the medical industry. Its biocompatibility makes it ideal for use in medical devices, ensuring both safety and long-term reliability. Whether you’re manufacturing surgical tools, implants, or research devices, it offers exceptional quality that meets the rigorous demands of medical environments.

Product Specifications

| Property | Value |

|---|---|

| Material | Gr9 Titanium (Ti-3Al-2.5V) |

| Thickness | 0.03mm – 1.0mm |

| Width | Customizable |

| Tensile Strength | 620 MPa |

| Yield Strength | 483 MPa |

| Elongation | 15% |

| Certification | ISO9001:2015, ISO13485:2016, EU CE |

| Corrosion Resistance | Excellent |

| Custom Specifications | Available upon request |

Product Advantages

- Lightweight & Durable: Gr9 Titanium Foil is exceptionally lightweight, offering enhanced flexibility and ease of use without sacrificing durability.

- High Strength-to-Weight Ratio: This material provides excellent structural integrity, making it ideal for applications that require both strength and mobility.

- Corrosion Resistance: Titanium’s natural resistance to corrosion ensures longevity, even in the most demanding environments.

- Biocompatibility: Gr9 Titanium is fully biocompatible, making it a safe choice for medical implants and other health-related applications.

- Customizable: Available in various sizes and thicknesses to suit specific customer needs.

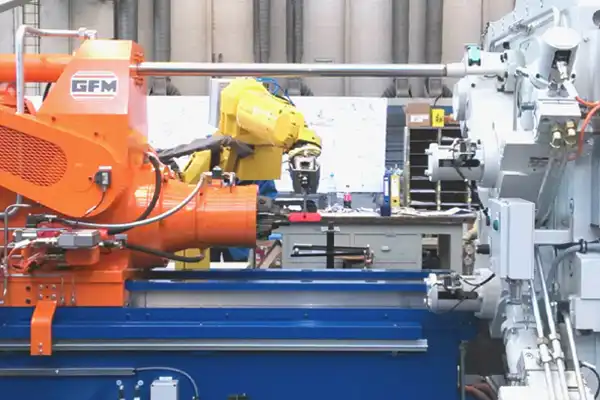

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

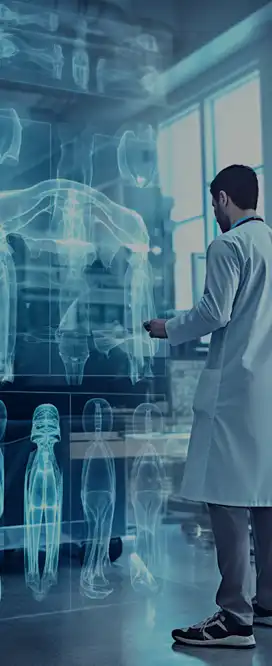

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

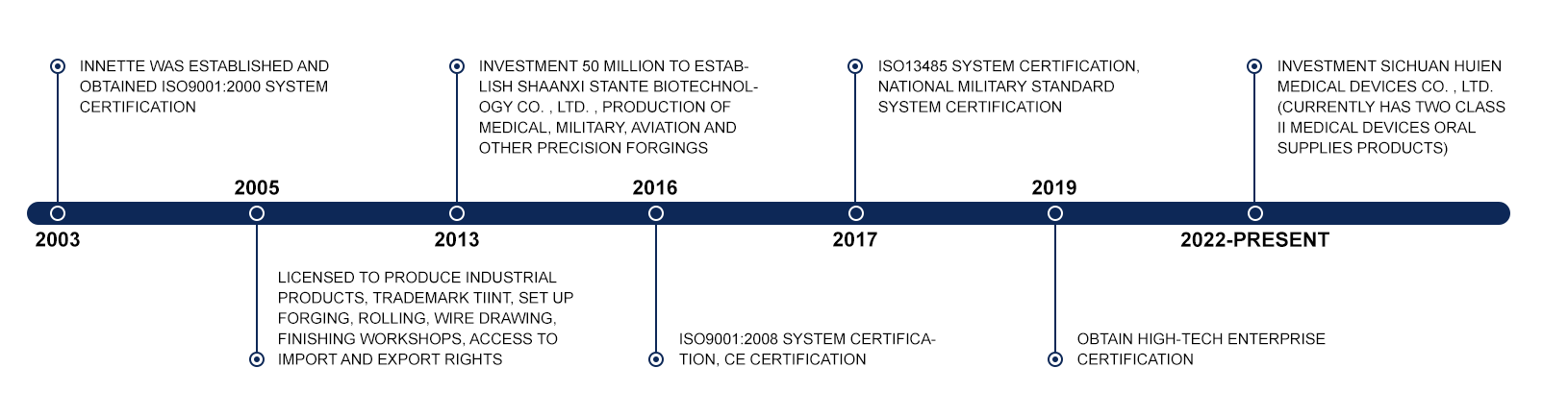

Our Factory - A Legacy of Excellence

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Service

At Baoji INT Clinical Titanium Co., Ltd., we work in giving far reaching OEM (Unique Gear Maker) administrations for it, custom-made definitively to your particular task needs. Our broad skill and cutting edge producing capacities empower us to offer profoundly tweaked arrangements that line up with your precise particulars. We comprehend that each venture is one of a kind and requires an unmistakable methodology, which is the reason we are focused on conveying items that fulfill the most noteworthy guidelines of value and execution.

Our group of committed experts works intimately with you all through the whole interaction, from starting discussion to definite creation. We are proficient at obliging an extensive variety of customization choices, remembering changes for thickness, aspects, and surface completions to guarantee that our product meets your careful necessities. Whether you really want particular medicines, exact resiliences, or explicit bundling arrangements, we are prepared to deal with all parts of customization with accuracy and care.

FAQ

1. What is the thickness range available for Gr9 Titanium Foil?

We offer a thickness range from 0.03mm to 1.0mm. Custom sizes are also available based on your needs.

2. Is the product suitable for medical implants?

Yes, Gr9 Titanium is biocompatible and widely used in orthopedic, spinal, and dental implants.

3. How does Gr9 Titanium compare to other titanium alloys?

Gr9 Titanium offers a unique balance of lightweight properties and strength, making it more flexible than Gr5 while maintaining excellent performance in medical applications.

4. Can you provide certification for your products?

Absolutely! All of our Gr9 Titanium products come with ISO9001:2015, ISO13485:2016, and EU CE safety certifications.

5. What is the lead time for bulk orders?

Lead times vary depending on order size and customization requirements, but we typically deliver within 4-6 weeks for standard products.

Contact Us

For more information or to request a custom quote, please contact Baoji INT Medical Titanium Co., Ltd. at export@tiint.com. Our team is here to help you find the perfect Gr9 Titanium Foil solution for your medical or industrial project.