Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit needs.

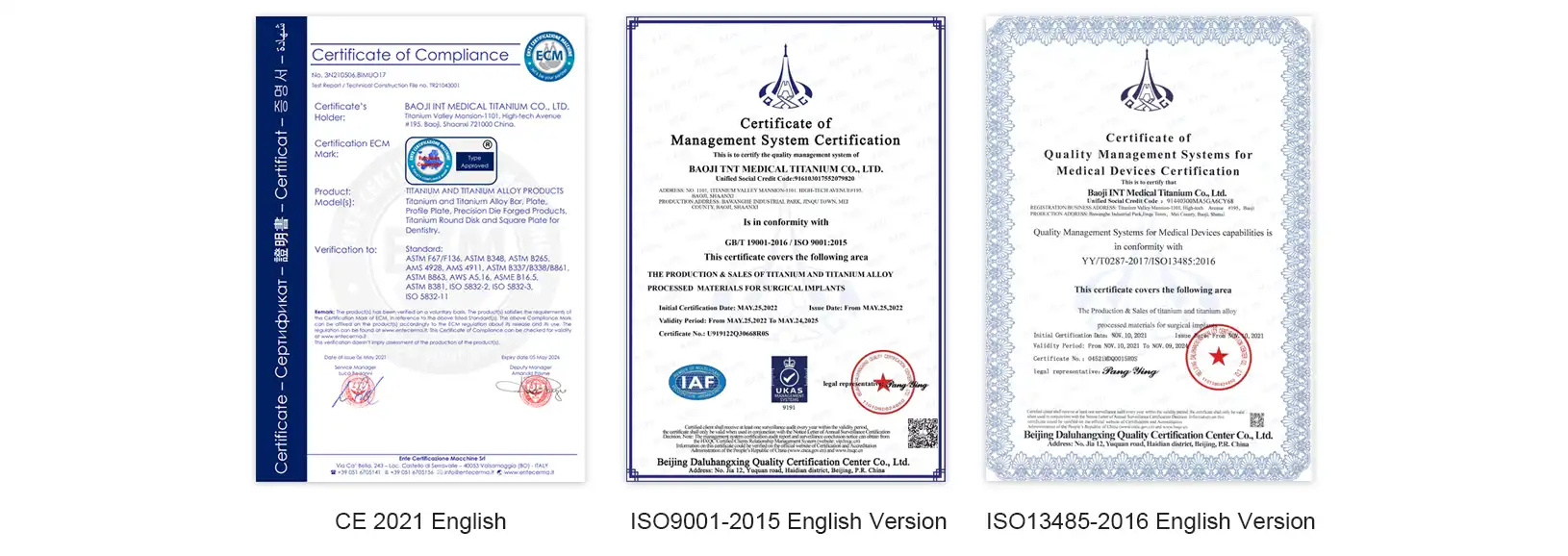

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

ERTi Titanium Welding Wire Introduction

Our ERTi Titanium Welding Wire addresses a top-level decision for clinical applications, famous for its extraordinary strength, solidness, and erosion opposition. Produced by Baoji INT Clinical Titanium Co., Ltd., this wire embodies our obligation to conveying excellent titanium materials that satisfy the demanding guidelines of the clinical business. The innate properties of it make it especially reasonable for use in a scope of clinical gadgets where execution and unwavering quality are vital.

Product Specifications

| Specification | Details |

|---|---|

| Material | ERTi Titanium (Grade 2, Grade 5, etc.) |

| Diameter Range | 0.8mm - 6.0mm |

| Standard Length | Customizable (Standard: 1m, 3m) |

| Surface Finish | Polished |

| Certification | ISO9001:2015, ISO13485:2016, CE |

| Application | Medical devices, implants, surgical tools |

| Packaging | Sealed vacuum bags |

Product Advantages

The product stands out for its lightweight and strength, making it ideal for precision applications. It offers:

- Corrosion Resistance: Long-lasting protection against environmental and biological degradation.

- High Strength-to-Weight Ratio: Ensures flexibility without compromising durability.

- Fatigue Resistance: Built to withstand repeated use and pressure over time.

- Customizability: We can tailor the wire to meet your specific medical device needs.

Technical Features

Our ERTi Titanium Welding Wire is engineered with advanced titanium alloys known for their biocompatibility and superior mechanical properties:

- Biocompatibility: Safe for use in medical devices that interact with human tissue.

- Low Thermal Conductivity: Ensures precision during welding, reducing distortion.

- High Melting Point: Suitable for high-temperature applications without deformation.

Product Applications

ERTi Titanium Welding Wire is essential for manufacturing and maintaining a variety of medical equipment:

- Orthopedic Implants: Used for joint replacements, bone screws, and plates.

- Dental Implants: Ideal for dental screws and prosthetics.

- Surgical Instruments: Perfect for precision tools like scalpels and forceps.

- Spinal Implants: Ensures durability and strength in fusion surgeries.

- Trauma Fixation Devices: Used in plates, screws, and pins for fracture fixation.

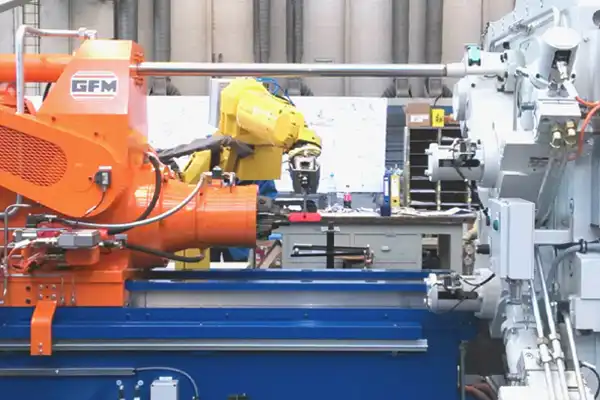

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

Our Factory - A Legacy of Excellence

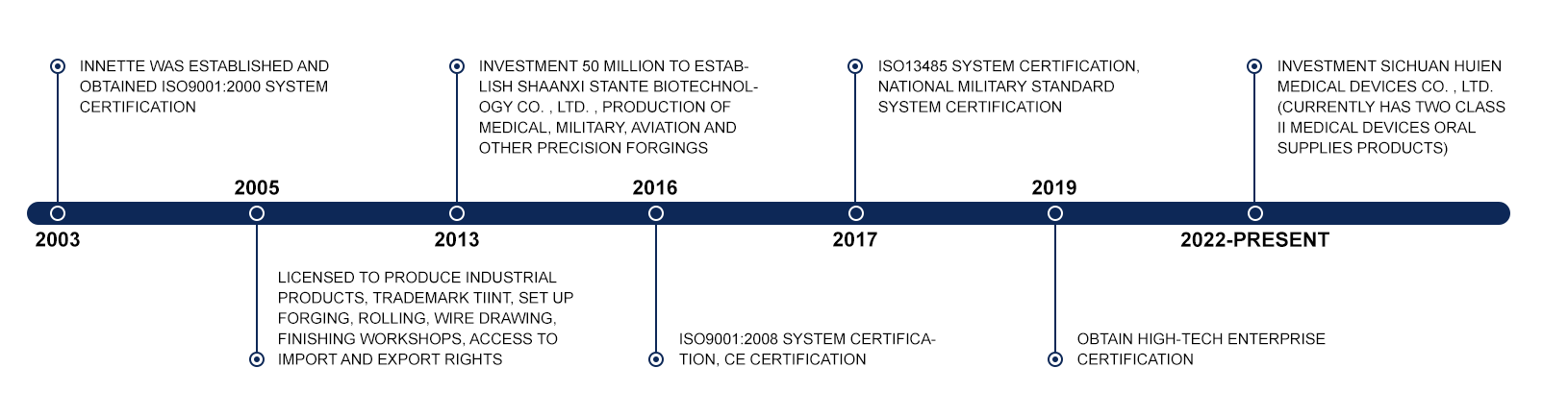

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Service

At Baoji INT Clinical Titanium Co., Ltd., we value offering thorough ERTi Titanium Welding Wire OEM benefits carefully customized to meet the remarkable necessities of your business. We comprehend that every client has unmistakable necessities, and we are committed to guaranteeing that our items adjust impeccably with your details. Our administrations include an extensive variety of customization choices to help your particular applications and improve your item contributions.

- Custom Sizes & Specifications

- Private Labeling

- Flexible Packaging Options

- Technical Support for Product Development

FAQ

-

What certifications does your product meet?

Our product is certified with ISO9001:2015, ISO13485:2016, and CE, ensuring compliance with international standards. -

Can I customize the diameter of the welding wire?

Yes, we offer a range of diameters from 0.8mm to 6.0mm, and custom lengths can be arranged. -

What industries can use ERTi Titanium Welding Wire?

Our wire is perfect for medical devices, dental implants, surgical tools, and orthopedic equipment. -

What packaging options do you provide?

We use vacuum-sealed bags for long-term storage and protection. Custom packaging is also available upon request. -

Do you provide technical support?

Yes, our expert team offers full technical support to ensure the correct application of our products.

Contact Us

For more information about our ERTi Titanium Welding Wire and other medical titanium products, please contact us at [export@tiint.com]. We look forward to partnering with you to deliver high-quality, safe, and reliable titanium solutions for the medical industry.