Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit needs.

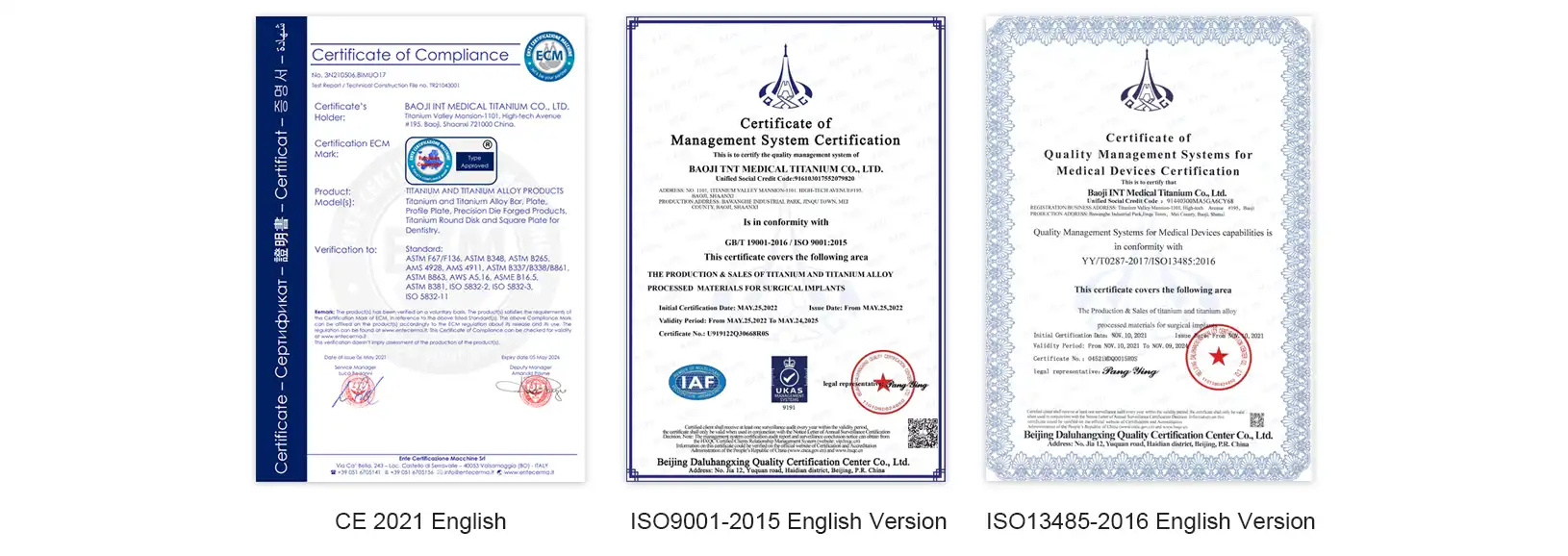

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

Gr 2 Titanium Tube Introduction

At Baoji INT Medical Titanium Co., Ltd., we have functional involvement with giving fantastic Gr 2 Titanium Tube things, known for their unrivaled biocompatibility and sturdiness. Our wide association with the clinical titanium industry ensures that we convey high level titanium materials for various clinical applications, including strong, dental, and cautious instruments.

The products are ideal for the production of cutting-edge medical technologies or medical devices because they possess the strength, resistance to corrosion, and flexibility required for the most demanding applications.

Product Specifications

| Material | Gr 2 Titanium (Pure Titanium) |

|---|---|

| Outer Diameter | Customizable (Standard sizes from 4mm to 114mm) |

| Wall Thickness | Customizable (Range from 0.5mm to 6mm) |

| Length | Up to 6000mm (Custom lengths available) |

| Standards | ASTM B338, ISO 5832-2 |

| Surface Finish | Pickled, polished, or customized |

| Certifications | ISO9001:2015, ISO13485:2016, EU CE certified |

|

|

Key Features

- Lightweight and durable

- Corrosion-resistant for long-term use in medical environments

- High strength-to-weight ratio for flexibility in design

- Excellent fatigue resistance ensuring long-lasting performance

- Customizable to suit diverse medical needs

Product Advantages

Our Gr 2 Titanium Tube provide numerous advantages, especially for medical applications:

- Biocompatibility: Safe for use in the human body without adverse reactions.

- Corrosion Resistance: Ideal for long-term implantation and surgical use in harsh environments.

- Flexibility: High strength-to-weight ratio, ensuring easy customization for different medical devices.

- Durability: Excellent fatigue resistance for consistent performance over time.

- Certifications: Fully certified to meet international safety and quality standards.

Technical Features

The products are planned with cutting edge innovative highlights to guarantee they fulfill the thorough needs of the clinical business:

- Purity: 99.5% titanium content guarantees great mechanical properties.

- Accuracy Designing: Made with tight resistances to guarantee dependable execution in clinical gadgets.

- Warm Solidness: Impervious to high temperatures during cleansing cycles.

Gr 2 Titanium Tube Application

Gr 2 Titanium Tube assume a pivotal part in different clinical gadgets because of their fantastic biocompatibility, strength, and lightweight properties. A closer look at their applications is as follows:

- Muscular Inserts: Due to their strength and durability, these tubes are frequently used in orthopedic procedures like joint replacements. They are likewise utilized in bone screws and plates, which are fundamental for settling cracks and advancing legitimate mending.

- Dental Inserts: Grade 2 titanium tubes play a crucial role in the construction of dental implants in the field of dentistry. They are utilized to make screws and prosthetic gadgets that supplant missing teeth, offering a dependable and durable answer for patients.

- Careful Instruments: The lightweight idea of Grade 2 titanium makes it ideal for creating careful instruments. This incorporates devices like surgical blades and forceps, which benefit from the material's solidarity and protection from consumption, guaranteeing accuracy and life span in surgeries.

- Spinal Inserts: Grade 2 titanium tubes are used in spinal implants designed for fusion surgeries in spinal surgeries. The spine is stabilized and aligned with the help of these implants, which aids in recovery and function.

- Injury Obsession Gadgets: For injury care, Grade 2 titanium tubes are used in break obsession gadgets. This incorporates plates and screws that assistance to get and settle broken bones, supporting viable and effective mending.

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.

Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

Our Factory - A Legacy of Excellence

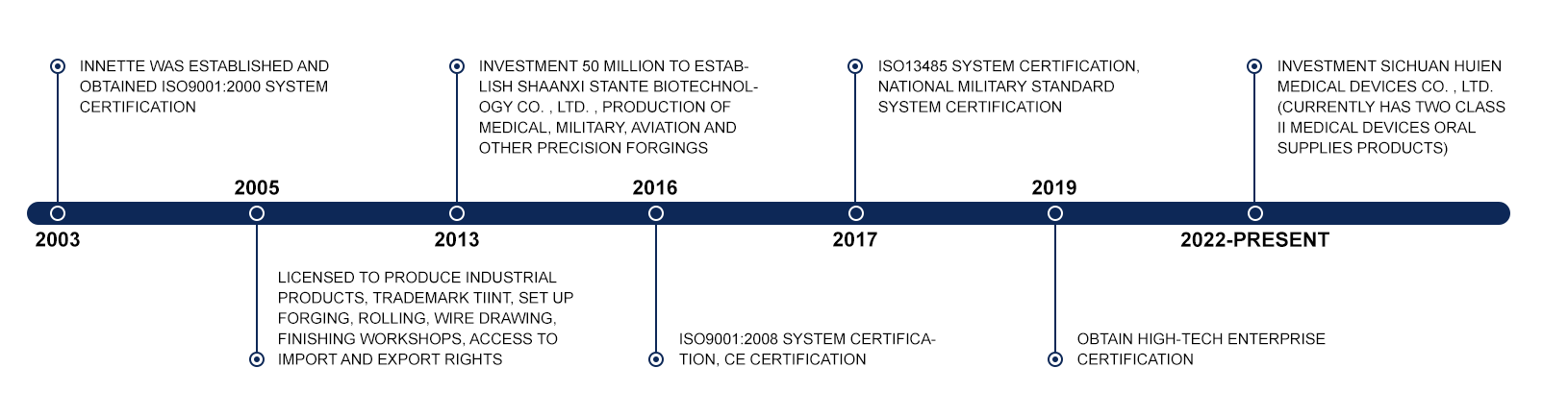

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Service

At Baoji INT Medical Titanium Co., Ltd., we offer altered OEM administrations. Our group teams up intimately with clients to foster the products that fit their novel determinations. We give fast prototyping, specialized help, and adaptable creation abilities to guarantee that your clinical gadgets meet all utilitarian and security necessities.

FAQ

Q1: What is the typical lead time for Gr 2 Titanium Tube orders?

A1: Lead time depends on the quantity and customization requirements. Standard orders can be delivered within 2-4 weeks.

Q2: Can I request custom sizes?

A2: Yes, we offer fully customizable diameters, wall thicknesses, and lengths based on your specific needs.

Q3: Are your products certified for medical use?

A3: Yes, all our titanium tubes comply with ISO9001:2015, ISO13485:2016, and EU CE standards.

Q4: How do you ensure the quality of your products?

A4: We follow stringent quality control procedures, including full traceability, to ensure every batch meets international standards.

Q5: What payment methods do you accept?

A5: We accept bank transfers, credit card payments, and other methods. Please contact us for further details.

Contact Us

For more information on our Gr 2 Titanium Tube or to request a quote, please contact us at export@tiint.com.