Corrosion-resistant for long-term use.

High strength-to-weight ratio for flexibility.

Excellent fatigue resistance for durability.

Customizable to suit needs.

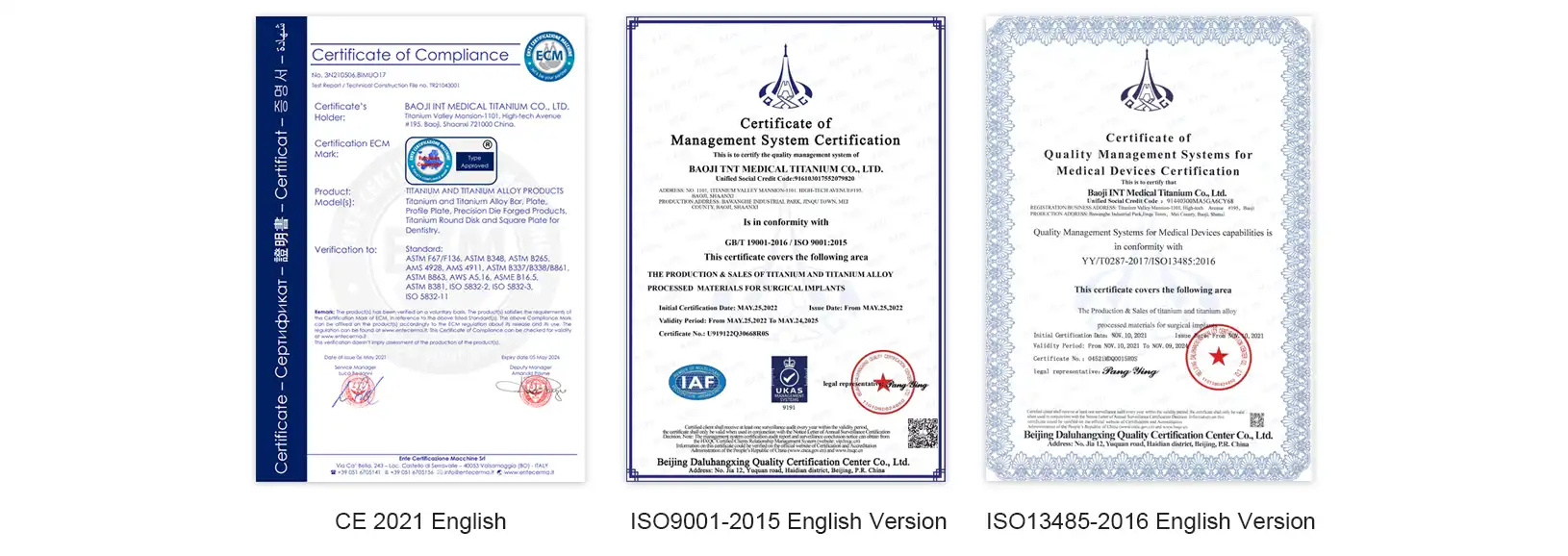

All products have passed ISO9001:2015, ISO13485:2016, EU CE safety certification

Gr9 Welded Titanium Tube Introduction

At Baoji INT Medical Titanium Co., Ltd., we spend significant time in creating excellent Gr9 Welded Titanium Tubes explicitly intended for clinical applications. As an innovator in the clinical titanium industry, we are focused on giving dependable and sturdy titanium materials for your basic clinical gadgets. Whether for inserts, careful instruments, or concentrated clinical apparatuses, our products conveys the strength, adaptability, and erosion opposition expected to guarantee predominant execution in requesting clinical conditions.

Product Specifications

| Property | Specification |

|---|---|

| Material | Grade 9 Titanium (Ti-3Al-2.5V) |

| Outer Diameter | 10mm to 60mm |

| Wall Thickness | 0.5mm to 5mm |

| Length | Customizable |

| Standard | ASTM B338, ISO 9001:2015, CE Certified |

| Surface Finish | Polished, Pickled |

| Tensile Strength | 620 MPa |

| Elongation | 15% |

| Corrosion Resistance | High |

Product Advantages

The Gr9 Welded Titanium Tube offers a range of benefits that make it an excellent choice for medical use:

- Lightweight and Durable: The titanium alloy composition ensures lightweight handling without compromising strength, ideal for medical tools and implants.

- Corrosion-Resistant: It withstands exposure to bodily fluids and sterilization processes, ensuring long-term durability in surgical environments.

- High Strength-to-Weight Ratio: Provides flexibility and ease of use in precise medical applications, minimizing material fatigue.

- Fatigue Resistance: Designed for repeated use, maintaining its structural integrity even in challenging conditions.

- Certified Quality: All tubes meet ISO 9001:2015, ISO 13485:2016, and EU CE standards for safety and performance.

Technical Features

The Gr9 Welded Titanium Tube is designed with high-performance characteristics in mind:

- Welded Titanium Construction: Ensures seamless joint integrity for demanding medical environments.

- Precision Manufacturing: Produced with advanced techniques to meet exact medical specifications.

- Compatibility with Medical Devices: Ideal for critical applications such as joint implants, surgical tools, and other biocompatible devices.

Gr9 Welded Titanium Tube Applications

In a wide range of medical and surgical applications, our products are renowned for their versatility and high performance. Among their most important uses are:

Medical titanium rods are used extensively in the healthcare industry due to their exceptional strength, corrosion resistance, and biocompatibility. They are indispensable in various medical fields, including orthopedics, dentistry, cardiovascular surgery, and neurosurgery. Here are some of the applications of medical titanium rods:

Orthopedics: Titanium rods are commonly used for internal fixation of fractures and spinal fusion procedures. The biocompatibility of titanium ensures that these implants integrate well with the surrounding bone, providing long-term stability and support for the patient .

Dentistry: In dentistry, medical titanium rods are utilized in dental implants, offering a durable and biocompatible solution for replacing missing teeth. The ability of titanium to osseointegrate with the jawbone makes it a preferred material for dental implants, providing patients with a reliable and long-lasting tooth replacement option .

Cardiovascular Surgery: Medical titanium rods find extensive use in cardiovascular surgery, where they are employed in the fabrication of stents, pacemaker components, and other cardiac implants. The biocompatibility of titanium ensures that these devices can be safely implanted within the body without triggering adverse reactions, offering patients a lifeline in the treatment of various cardiovascular conditions .

Neurosurgery: In neurosurgery, medical titanium rods are utilized in the construction of cranial plates, spinal implants, and other neurosurgical devices. The lightweight nature of titanium, coupled with its strength and biocompatibility, makes it an ideal material for such applications, providing neurosurgeons with the tools they need to perform intricate procedures with precision and confidence .

Product Technology and Production Process

Hot rolling and forging techniques that enhance the mechanical properties, ensuring superior strength and toughness.

Ultrasonic testing to detect flaws and ensure 100% reliability.

Strict quality control at every stage of production, meeting and exceeding international medical standards like ISO9001:2015 and ISO13485:2016.

|

|

|

|

|

|

|

|

Industries Catered

Our products are widely used in medical, automotive, aerospace, chemical, scientific and technological manufacturing and electronic information industries.

|

|

|

|

|

|

Our Factory - A Legacy of Excellence

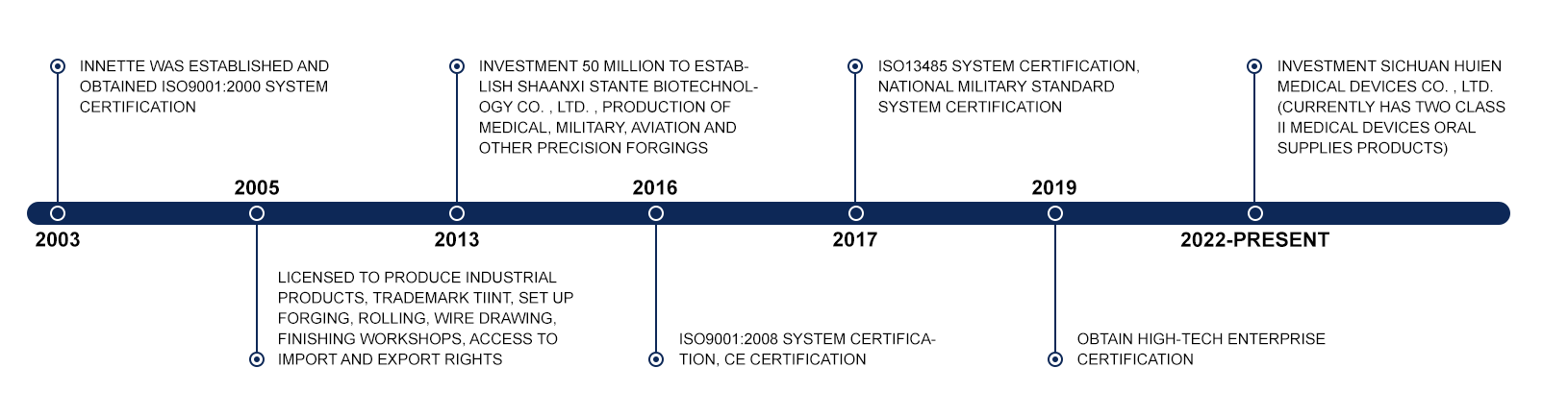

Founded in 2003 by titanium industry expert Mr. Zhan Wenge, Baoji INT Medical Titanium Co., Ltd. has grown into a benchmark enterprise in the R&D and production of medical titanium materials. With more than 30 years of experience, INT is deeply invested in the development of high-quality titanium for the medical sector. We provide a full range of titanium products, including pure titanium, Ti6Al4V ELI titanium, and custom titanium alloy forgings.

|

|

|

|

|

|

|

|

Packaging and Transportation

|

|

|

Why Choose Us?

Choosing Baoji INT Medical Titanium Co., Ltd. means partnering with a trusted leader in the medical titanium industry.

Here’s why:

Proven Expertise: Over 30 years of experience in medical titanium production.

Advanced Technology: State-of-the-art production lines and equipment.

International Certifications: ISO9001:2015, ISO13485:2016, and EU CE certifications.

Comprehensive Support: We provide ongoing technical support, ensuring our products fit seamlessly into your manufacturing process.

Customer-Centric Approach: Committed to delivering high-quality products on time, every time.

For inquiries or orders, please contact us at export@tiint.com. We look forward to partnering with you for your medical titanium needs.

OEM Services

We offer customization choices for our products, custom-made to meet your careful requirements. Our group offers full specialized help to guarantee your items satisfy the most elevated clinical guidelines. Whether it's custom estimating, explicit surface medicines, or tailor made bundling, we are here to convey.

FAQ

1. What certifications do your Gr9 Welded Titanium Tube have?

All products are ISO9001:2015 and ISO13485:2016 certified and meet EU CE safety standards.

2. Can I request custom sizes for medical device manufacturing?

Yes, we provide fully customizable options to suit your specific requirements.

3. How durable are these tubes for long-term medical applications?

The Gr9 Titanium Tube is highly corrosion-resistant and designed to maintain structural integrity even under continuous use.

4. What is the delivery time for bulk orders?

Typically, orders are processed and delivered within 30 to 45 days, depending on the size and specifications.

5. How can I place an order?

You can reach us directly via email at export@tiint.com to discuss your needs and request a quote.

Contact Us

For more details on our Gr9 Welded Titanium Tube or to request a quote, feel free to contact us at export@tiint.com. We look forward to working with you to meet your medical titanium material needs.